Plot.No-399, F.F, Block–L, Lane-11, Mahipalpur Extension, New Delhi 110037

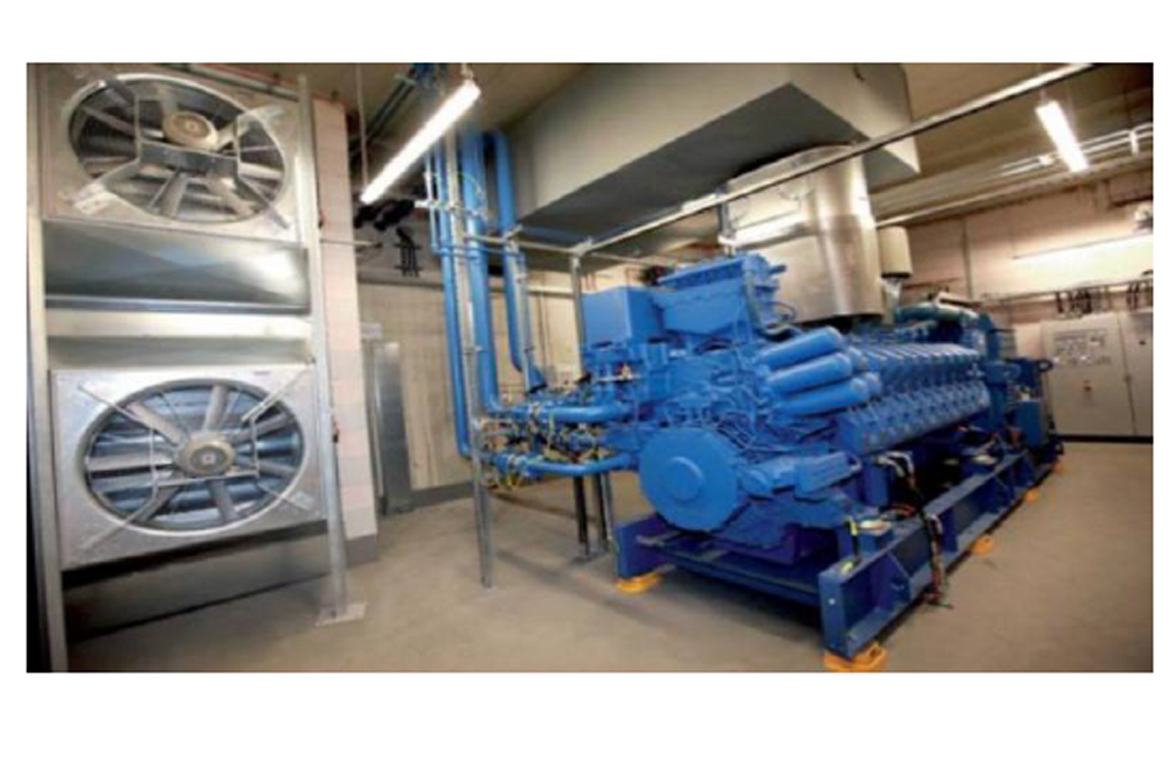

DG Room Cooling Systems

Each generator set manufacturer offers different options for design of the cooling system. The two most common styles of cooling systems are closed loop and open loop systems. Closed loop systems incorporate cooling pump(s), cooling fan and radiator(s) located on a skid as an all in one unit. In addition, container and trailer options are offered.

An ethylene glycol based coolant is circulated through the cooling system components. Three common cooling system configurations are:

Radiator cooling is the most common method of cooling gen set engines. Simple and practical, they fit most applications’ needs. All CAT gen sets can be equipped with various sizes of radiators mounted on the front of the unit. However, remote radiators can be used when adequate airflow through the gen set enclosure is not possible.

Most radiators are made up of tubes surrounded by fins (the core) that extract heat from water pumped through the system from the engine. Designed for 120 F ambient temperatures, they work best when correctly matched to engine power, ambient temperature and adequate airflow.

Copyright 2019 All Rights Reserved Designed By OGEN Infosystem Website Designing Company in India